- Electroslag Remelting of steel can achrieve the highest degree of cleanliness regarding certain types of inclusions

- Through the influence on the macro and micro configuration, it is possibleto achieve special technological and physical properties of steel

- Emphasis on the isotropy of the characteristics which are achievable by an optimal combination of technological parameters of overflow and hot processing

- With this procedure we can achieve a very low content of harmful sulful. The content of sulfide, oxide and other inclusions can also be greatly reduced.

- The quality of the macrostructure in ESR steel is, primarily, higher density of the steel and the internal ingot compactness.

- Macro and micro segregation are reduced to a minimum and as a result, ESR steel can be used in the unprocessed condition due its homogeneity, which is becoming a common practice

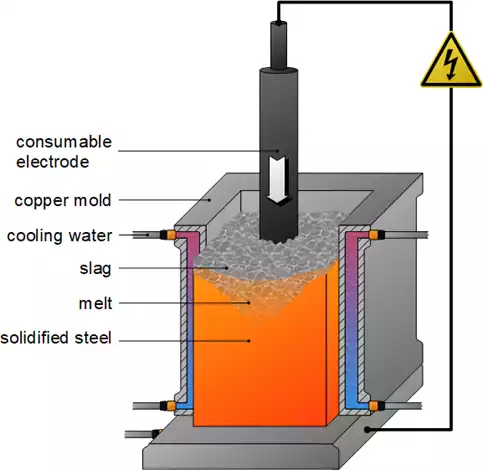

ESR process graphic scheme.

Advantages of ESR:

- High internal compactness and homogeneity of the ingot

- High purity of pre-cast steel, given the proportion of non/metallic inclusions (oxides, sulfides)

- 40-60% less of non-metallic inclusions (oxides, sulfides) compared to steel produced by other processes

- Better micro structure of steel

- Increased plasticity and mechanical properties of steel in the longitudinal and transverse directions

- Significantly increased impact strength, specially in the transverse direction

- Uniform structure of steel without rough segregation

- Significantly better endurance under dynamic load

- 60- 70% less sulfur than steel produced by other processes

- 10-60% less oxygen than steel produced by other processes

- Better polishing ability and better hot plastic processing ability

- Higher toughness

- Better stability and shape resistance, and increased wear resistance

- Increased anti-corrosion resistance and reduced pitting sensitivity

Our products:

- Production of standard and non/standard products on customers request

- Work plate W.Nr. 1.2343 ESU

- Work plate W.Nr. 1.2344 ESU

- Work plate W.Nr. 1.2714 ESU

- Work plate W.Nr. 1.2379 ESU

- Work plate W.Nr. 1.2312 ESU

The circular form of the ingot from Ø360 to Ø750, weight up to 2300 kg, length from 50 up to 1000 mm.

Heat treatment

During rough mechanical processing, straightening, etc., internal stresses remains in the steel, which should be removed or at least reduced before hardening. Reduction of deformations is achieved by appropriate preliminary annealing.

Annealing to reduce internal stresses before the final fine treatment is mandatory if there are special requirements for dimensional stability during the following heat treatment.